How to Get My Replicator Printing Well Again

Stops Extruding Mid Print

Your 3D prints keep failing function-way or about a half-hr into printing.

Troubleshoot It

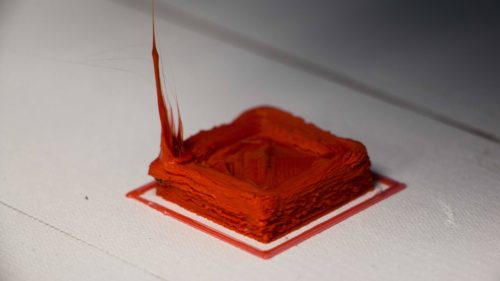

Nether Extrusion/No Extrusion

There is no filament coming out of the nozzle or filament is "crimper" out of the nozzle.

Troubleshoot Information technology

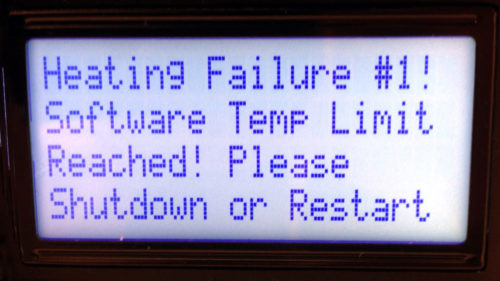

Temp Regulation & Heating Issues

Your machine is non maintaining heat or receiving "Heating Failure" codes.

Troubleshoot Information technology

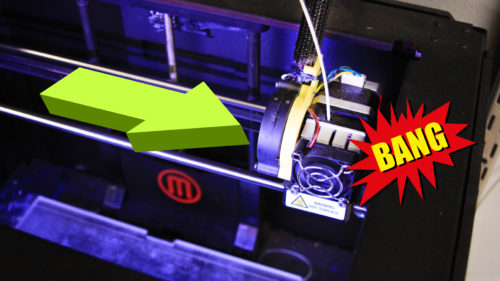

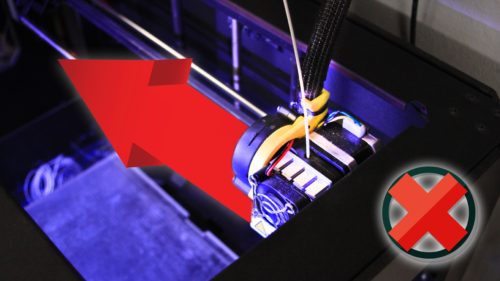

Printer Heads Crashing Into Sides

If the printer caput does not stop traveling before banging into the side of the printer.

Troubleshoot It

Stuttering/Skipping/Layer Shifts

Do y'all hear a stuttering at the aforementioned location each layer? Is your printer shifting layers?

Troubleshoot It

Stepper Motor Non Operating

If any of the stepper motors are non running, or running merely not operating.

Troubleshoot It

Motor Running, Gantry Not Moving

The motor is operating, but the extruder head is non moving along the gantry.

Troubleshoot Information technology

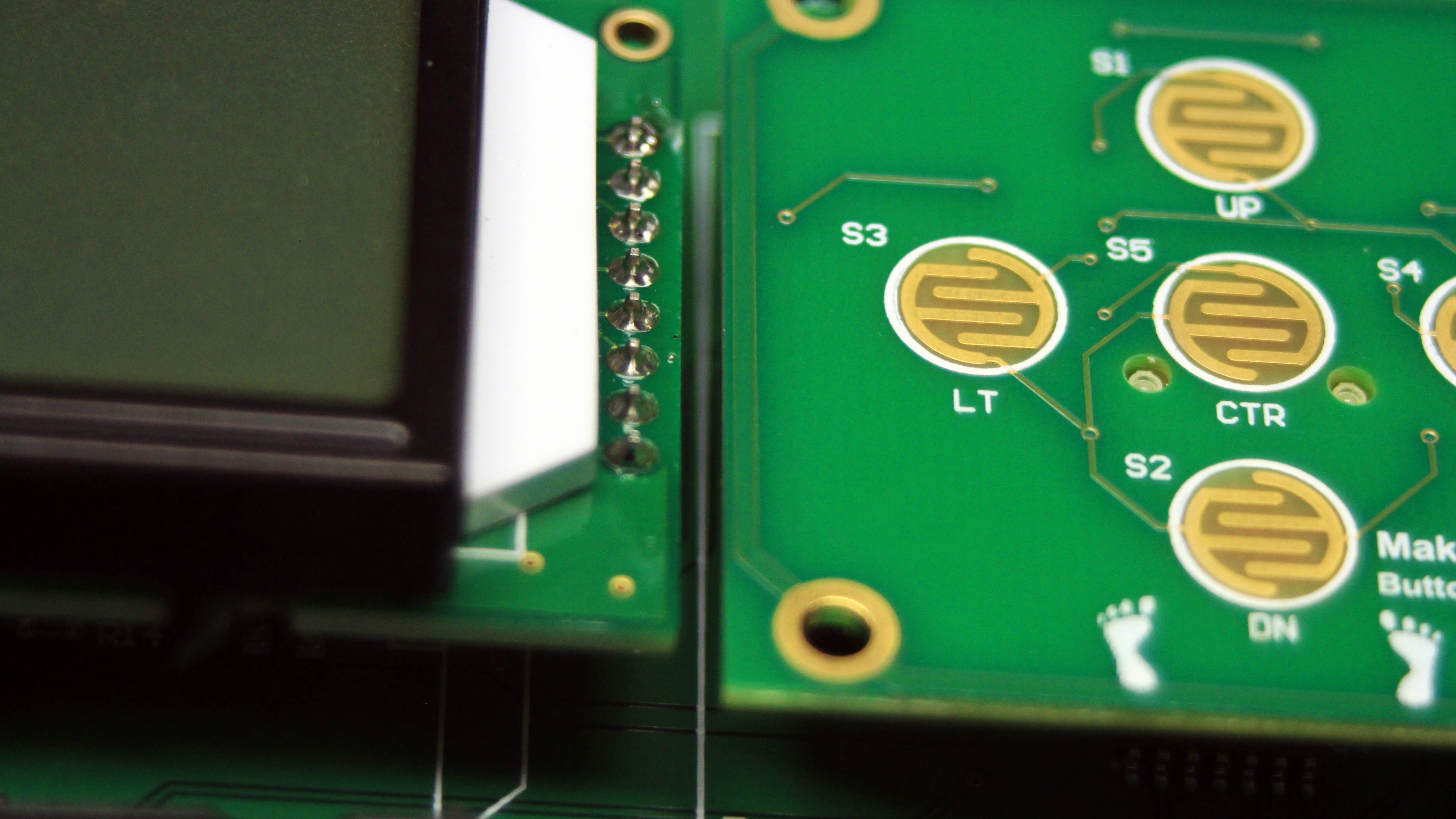

Interface or SD Not Working

Whatever issues with interface screen or buttons, the SD card reader, or the card itself.

Troubleshoot It

Need More Aid?

While y'all may be up to the challenge of addressing problems with your MakerBot, yous don't have to go it solitary. Take advantage of our3D Printer Repair Service. We offering serialized tracking, half dozen on-site technicians, and a fast turnaround. We'll get you support and printing.

Utilise the arrows to scroll through the parts you will need to check to solve this issue.

Stops Press Mid-Impress

Your front fan, or extruder fan, is the square shaped fan at the front of the printer head. If information technology is facing the incorrect manner, it's non venting enough rut away from the hot stop and is causing your print to fail. Make sure the label is not visible, facing inward. If you come across the label is facing outward, first remove the fan guard, then the fan, and reassemble in the proper management.

Notice the speed of the fan. It should be obvious if the fan is operating too slowly, as you will be able to discern, even slightly, the blades while they are spinning. At total speed they should exist well-nigh invisible. Your fan hardware is worn out, you volition want to purchase a new fan.

Check your fan blades while the machine is turned off. You may demand to remove the fan guard. If any are missing, you will need a new fan.

Your oestrus sink is backwards if the fins are facing inward toward the extruder assembly. Installed this way, it can't properly dissipate heat away from the assembly. Remove your fan guard, fan, and heat sink. Reinstall all pieces facing properly.

Make sure the fan spacers are between the fan and the rut sink and not between the estrus sink and the bar mountain.

Using low quality filament tin crusade legitimate problems. Filament with bad diameters and ovalities volition consistently crusade more clogs, jams and overall issues. Expect for filament of reputable quality (we offer high quality 3D-Fuel filament with spool ovality measurements on each box) to avoid these issues.

Utilise the arrows to scroll through the parts you will need to cheque to solve this issue.

Under Extrusion/No Extrusion

If filament is non coming out of the nozzle, or filament is "curling" out of the nozzle, the crusade of these issues is most likely heat pitter-patter. You'll find here dissimilar solutions to that problem. Even so, there may be farther hardware bug beyond heat pitter-patter. Take a look.

You may have a minor piece of melted filament stuck to your drive gear, preventing it from pushing filament through to the extruder. Learn how to clean your drive gear here.

Check your front extruder fan to be certain it'due south facing the correct direction (the characterization should be subconscious and facing inward). Then, while your MakerBot is turned off, bank check that the fan notwithstanding has all of its blades. Either of these issues will cause poor temperature regulation and estrus creep. If your fan is missing blades, find a replacement hither.

A properly installed oestrus sink volition have the fins facing outward toward the front extruder fan. If yours is installed with the fins facing toward the extruder assembly, first remove the front fan, then the heat sink and install them properly. Exist sure the fan is also reinstalled correctly with the label facing abroad from you.

One-time or ripped ceramic insulation tape (or no insulation tape at all) that sits around your heater block will cause irregular heating and heat creep. Install some fresh ceramic tape pieces.

Your nozzle and thermal bulwark tube may not be seated flush within the heater block, significant in that location is an open space where filament isn't guided through and melted properly. You'll know this if: the nozzle is tight, yet you are able to unscrew the thermal bulwark tube past hand,OR if you've experienced filament oozing out of the heater block.

Unscrew the nozzle a few turns, then tighten the barrier tube a few turns. Finally screw the nozzle dorsum on until it is tight. The proper height of the thermal barrier tube is if the lesser surface of the notch is level with the surface of the heater block.

If filament is sticking to the inside of your thermal barrier tube, first try the one-time pull a fast one on of lubing the within of your barrier tube with vegetable oil.

Y'all may be having heat creep issues. Click through to read more.

Also consider whether or non the filament you lot are using is of high quality. If filament has filler material and/or bore issues, consider a better filament option.

If your MakerBot Rep 2 is still nether-extruding or not extruding at all, AND you lot accept checked for every common cause of heat creep listed above, your drive block spring may be worn out. This is a rare occurrence, but still possible. A worn out spring volition not provide enough tension on the drive gear, and filament will not be pushed through. Observe a new Drive Block Spring here.

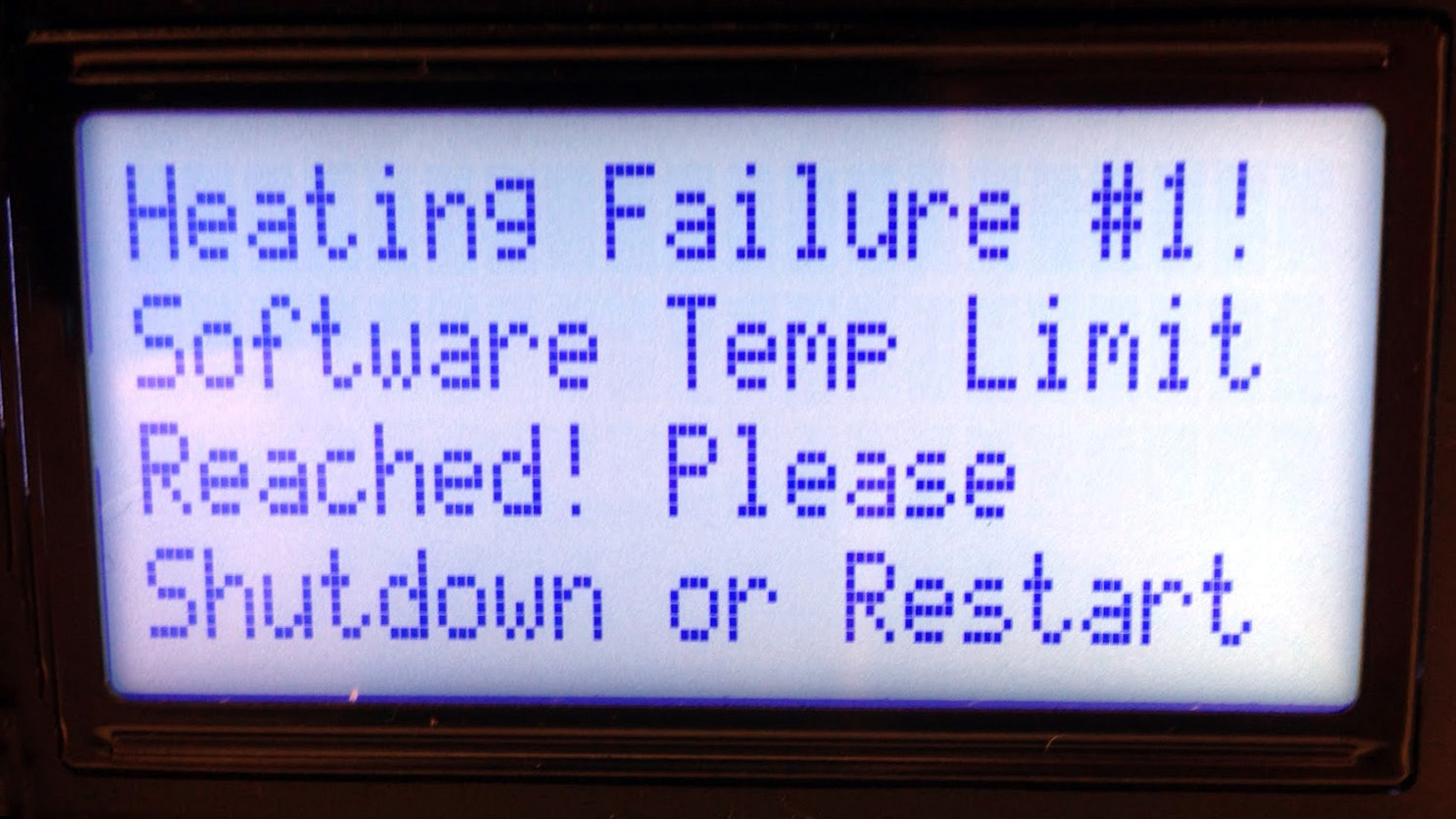

Heating Issues and Temperature Regulation

You are having issues with temperature regulation on your MakerBot Replicator 2 if you are receiving "Heating Failure" error codes. As e'er, the first course of action is to restart your auto.

You may exist experiencing heating issues because of heat creep. This may be due to insufficient heater cake insulation, front extruder fan, heat sink, or improperly seated thermal bulwark tube. Solve your heat creep problems here.

The simple solution, as noted in the MakerBot user transmission, is to navigate to Info and Settings > Preheat Settings. If information technology's set to a temperature to a higher place 300C, reset information technology to the correct preheat temperature and restart the machine to remove the error code (Heating Failure #1). However, you will most likely find your machine is not ready incorrectly. This means that your thermocouple has failed to provide authentic readings and will demand to exist replaced. Read next.

Run a pre-heat. If your automobile is displaying that it is not heating upward, but you lot observe that the heater block is really heating up, this is likely a faulty thermocouple.

But nonetheless check the connections on the thermocouple to the assembly. If things are still non operation properly, the thermocouple will need to be replaced.

Recollect it's important that the wires are not cleaved, bent, or damaged. This can happen easily then exist conscientious. It volition cause failures, even if but intermittently.

Find a replacement thermocouple here.

Once more, run a pre-rut. If the heater block does non get hot, it's most likely your heater cartridge that has failed. Check the connections betwixt the heater cartridge and the main extruder cable bundle. If yous nonetheless don't get any results, the heater cartridge is faulty and will need to exist replaced.

In rare instances, your MakerBot's power supply may not be delivering enough voltage to power the heater cartridge, or the motherboard itself has failed. You are able to mensurate the voltage of these components at home with the correct tools.

However, if y'all find yourself likewise deep in the weeds with this consequence, these are things we can diagnose with our in-house repair service. Bank check it out here.

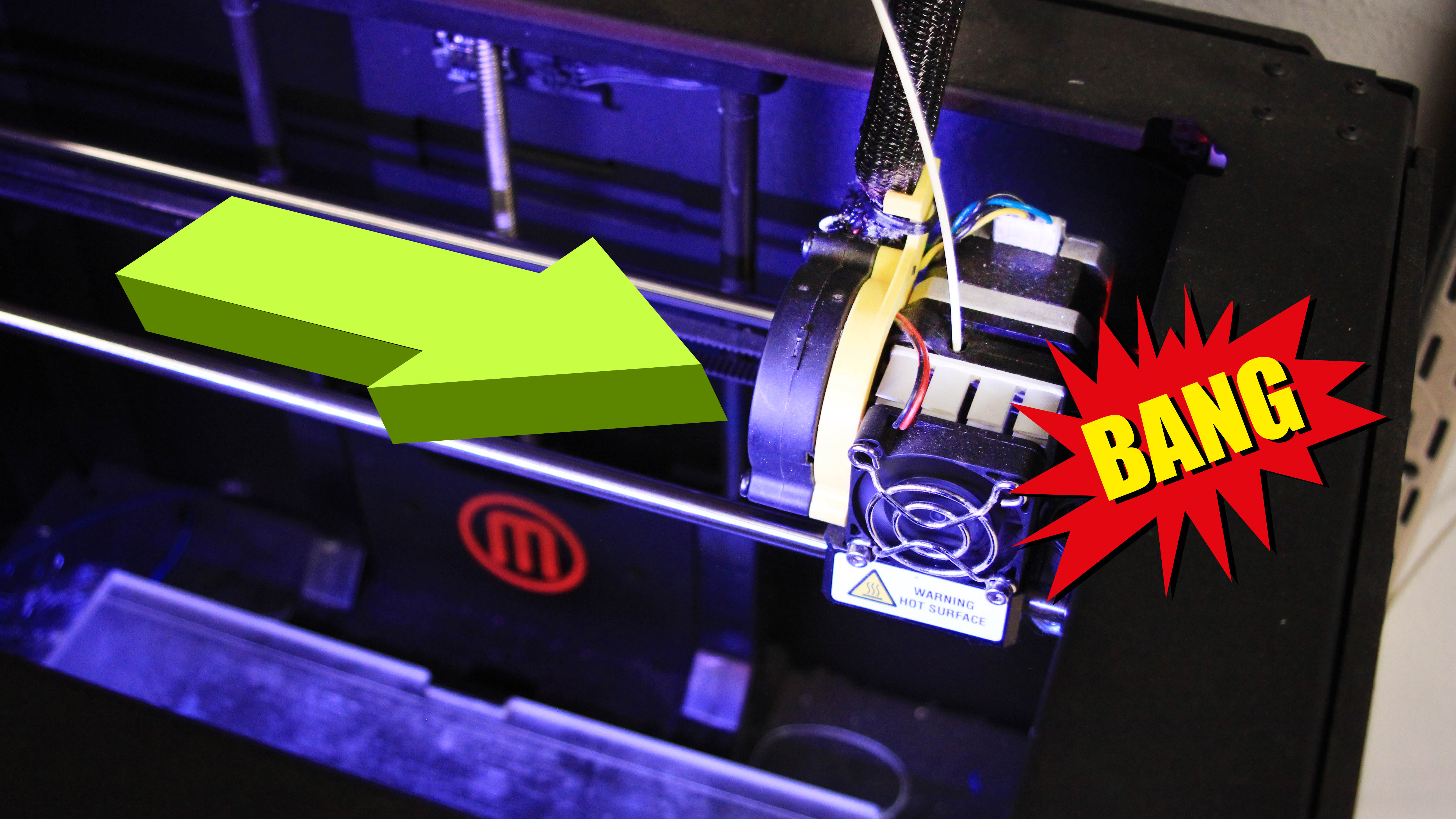

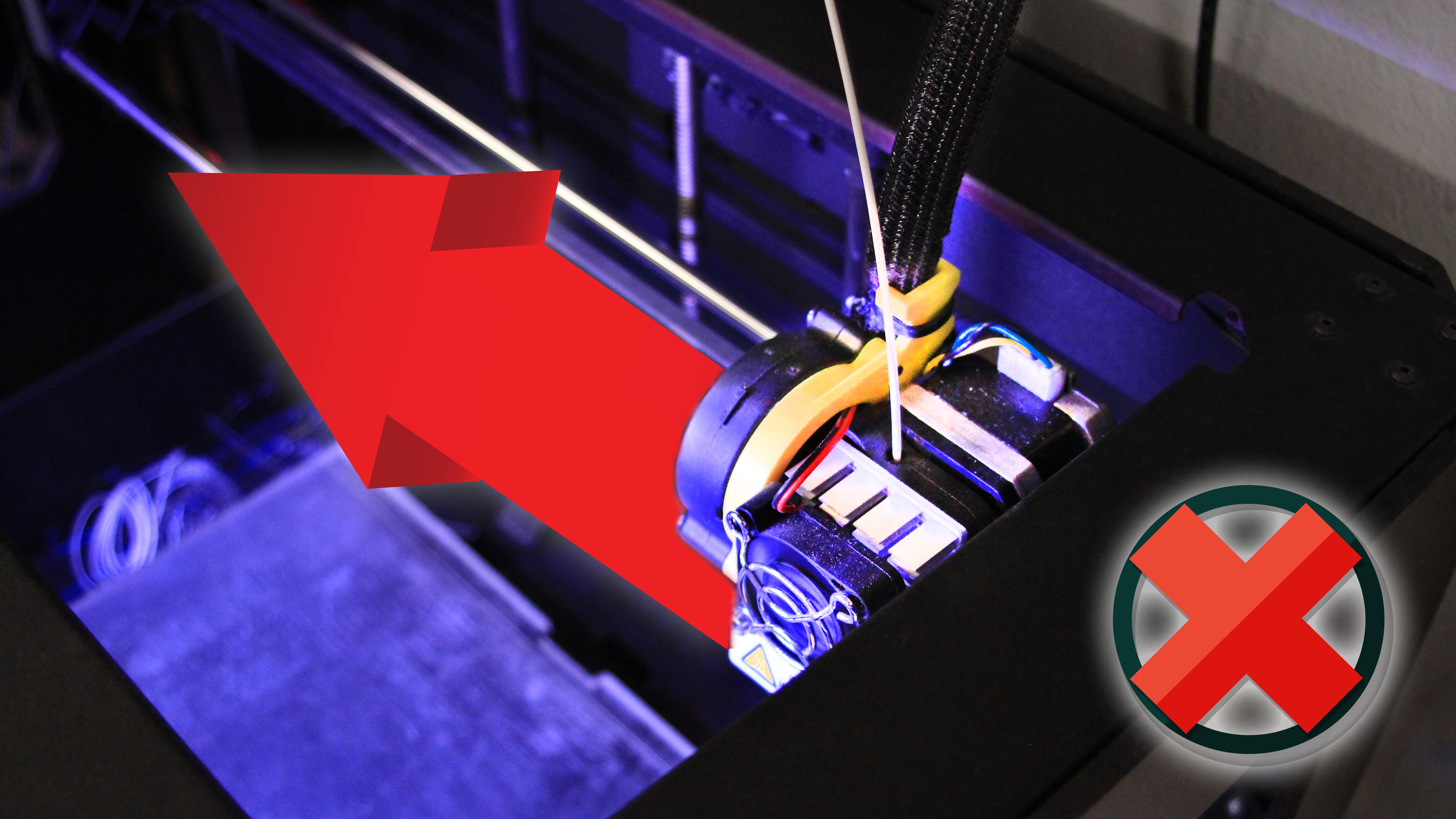

Printer Head Crashing Into Sides

If your extruder is banging into the sides, yous are having issues with your endstops. Endstops tell the machine when the extruder has traveled to the stop of the 10,Y, or Z centrality. There are iii endstops, one for each axis, on your MakerBot Replicator 2.

Your commencement course of activeness to run across if your endstop needs to be either adjusted or replaced is to press the button or lever of the endstop in question. If a red lite is illuminated, the part is working just may take been bumped and needs to be adjusted. Learn how here.

If there is no red light, check the connections and try over again. If y'all still do not see a cherry-red light, either the endstop or the cables will need to be replaced.

Closely audit the connecting cables on the endstop in question. Is there any fraying, crimping, or any other impairment? If so, they will need to be replaced.

If y'all have checked your connections, and the condition of your cables, and however practice not see a red light, your endstop will need to be replaced.

Stuttering / Pace Skipping

You may encounter a common problem involving the layers of your (otherwise perfect) impress shifting, or that your printer skips on the X-axis. You may as well notice your prints shift on an XY diagonal.

Check all connections to the stepper motor to ensure they are not merely loose. Starting time a new print and see if the problem continues.

The problem may be with your machine's firmware. Update to the latest version and revert your Replicator ii to the factory settings.

Find the Ten-axis pulley next to the Ten motor. With a hex key, tighten the pulley's chow spiral. Find the Y-axis pulley and do the same.

If your belts are too loose, they may exist causing print layers to shift or the extruder head to skip.

Inspect your X/Y/Z motor cables. Are they frayed or crimped in any areas? If so, they will probable need to be replaced. Find a replacement hither.

There are iv BotSteps connected to the MightyBoard on your MakerBot. They are the driver fleck for your stepper motors. They're small and tin can sometimes blow with a loud fissure and smoke. Simply you lot may non exist able to tell if this has occurred.

To begin testing the BotSteps, make sure to snap a flick of the MightyBoard so reinstall goes properly. Then, swap the z-axis chip with the chip related to the axis on which your printer is stuttering. If the trouble is resolved, you know that your BotStep needs replacing.

Stepper Motor Not Moving

These are possible solutions if your stepper motor is not running or working properly.

Check all connections to the stepper motor to ensure they are not but loose. Check your cables, every bit well, to ensure they are not frayed or crimped.

Check all the pins. Make sure none are bent or broken.

There are four BotSteps continued to the MightyBoard on your MakerBot. They are the driver chip for your stepper motors. They are small and can sometimes blow with a loud cleft and fume. But y'all may not be able to tell if this has occurred.

To begin testing the BotSteps, make sure to snap a moving picture of the MightyBoard then reinstall goes properly. Then, swap the z-axis flake with the chip related to the axis on with your printer is stuttering. If the trouble is resolved, you lot know that your BotStep needs replacing.

If the stepper motor is not moving, you may have loose belts.

Carriage Not Moving On The Gantry System

Power, heat, motors, extruder. Everything on your 3D printer seems to be working, just your carriage is not traveling along the gantry. What'due south up? Take a look.

A gantry that isn't moving is a sure sign of belts that demand to exist tightened. Check both.

Bank check your pulleys. It is possible that everything may exist set correctly, merely the ready screws are not tight plenty and everything is spinning in place. Give them a practiced tightening. Learn more here.

The belt clips connect your extruder wagon to the belt. Check that they are non broken, which would cause the belts to fail to move the gantry. Replacement belt clips may exist purchased in our store.

The stock carriage on the MakerBot Replicator 2 is a simple manufactured plastic slice and is prone to warping or even melting. If the carriage is so warped it is prevented from smoothly travelling along the rods, it will need to be replaced. Replace the plastic carriage here. Or to avoid this outcome forever, take a expect at our Aluminum Railroad vehicle.

Interface Buttons or LCD Screen Non Working

Dealing with the electronics problems on your MakerBot Replicator ii or 2X can end up being far more difficult to deal with than hardware issues. Hither'southward some advice to get you started. In the end, if your issue still is not resolved, nosotros highly recommend sending our repair service for your machine.

If you're having screen issues, check that the ribbon cable backside the LCD screen interface board is properly connected.

Remove the entire screen interface from the body of the machine. Disconnect the ribbon cablevision. Unscrew the back of the apparatus and remove the board. Using a q-tip and rubbing alcohol, gently clean the circuit board and the button nodules on the back of the prophylactic push overlay. Carefully reassemble.

What size SD card are you using? MakerBot's often don't like to read cards larger than 2GB. They're increasingly harder to detect that minor, but we accept SD cards in stock.

Buttons on the MakerBot Rep 2 interface may start to clothing out. You lot'll find yourself needing to press very hard to control the card.

Afterward removing and opening the entire LCD screen case, remove the black rubber button overlay. To exam whether your event is the buttons or the lath, utilise a pocket-size object with a metal end to printing the buttons on the board. If they work, your lath is functioning fine.

The issue is that the nodules on the back of the rubber button interface are non properly connecting. Yous may try wrapping a very small-scale slice of aluminum foil around the nodule to try to accomplish better connectivity. Also try conductive paint, which can exist purchased at nigh craft or hobby stores.

When your bot steps are declining, they can cause problems with your MakerBot'southward LCD screen. Unplug your automobile, turn it on its side, and remove the bottom plate to admission the motherboard.

Remove all 4 bot steps if you have a Rep 2, all 5 if you have a Rep 2X. Ability up your machine. If the LCD screen lights up, the issue is i or more than of your bot steps. Supersede them one by one (turning off the power each time) until the screen event returns. That is your faulty bot step. Information technology is of import when reinstalling these parts to never replace them upside downward. Delight carefully read more about diagnosing your bot steps. Find replacements here.

A faulty LCD carrier lath will cause issues with your screen or reading the SD cards. The only fashion to test for this is with a new LCD board. Make sure you have troubleshooted for the other possible causes earlier this stride. You may seek out a new LCD screen board, or send your machine into our 3D Printer Repair Service to permit our technicians to test and repair this problem.

A blown motherboard is the concluding option to consider for your LCD screen or SD card issues. Visit our How-To pages to learn more nearly diagnosing your MakerBot's Mightyboard. For replacement/diagnosis of this part, nosotros recommend our 3D Printer Repair Service.

Source: https://www.fargo3dprinting.com/how-to/troubleshoot/makerbot-replicator-2/